The field supervisor’s first indication of a flooded contactor tower is usually a report of excessive glycol loss. A check of a lowpoint bleeder on the gas pipeline downstream of the tower will show glycol. After refilling the glycol reboiler, the level in the reboiler gauge glass noticeably decreases after a few hours. This is a further indication of flooding. Of course, a dehydration system loosing glycol this fast cannot dry natural gas on a continuous basis.

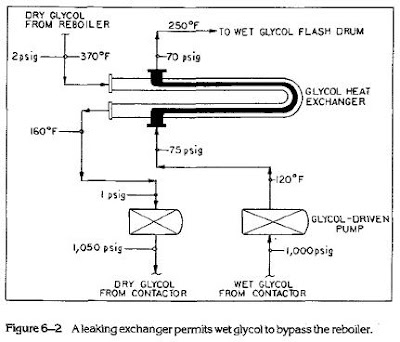

One simple explanation of such glycol losses is a leaking dry gas to dry glycol heat exchanger (Figure 6-2). Note that the glycol pressure in this heat exchanger will be slightly higher than the gas pressure. To check for leakage, shut off and block in the glycol pump, block in the dry glycol at the contactor tower, and open an intervening bleeder between the pump and the tower. If gas does not blow out of the bleeder, the exchanger is not leaking.